Handy set of accessories for servicing and maintenance work

Non-rebound hammer substitute – even in hard-to-reach places

Space is often too scarce to use a hammer in the best possible way when performing servicing and maintenance work. However, this issue is of no concern with the drop-mallets made by Erwin Halder KG. This is because they allow for safe work with low noise and reduced strain on the joints – even in areas with limited accessibility. Halder’s new box set combines a selection of the handy drop-mallets with a variety of punches. This ensures that the user will always have the right tool close at hand.

“We are in constant communication with scores of specialists working in a wide variety of trades in an effort to enhance our portfolio and improve our products. What we have gathered from these exchanges is that users often “cook up” their own solutions in a bid to execute work in places with spatial limitations. But, this is not necessary in many cases! For many use cases, our product range already offers a matching tool, e.g. drop-mallets and punches”, reveals Volker Gernth, Sales Director Hand Tools at Erwin Halder KG.

A soft mallet without a handle

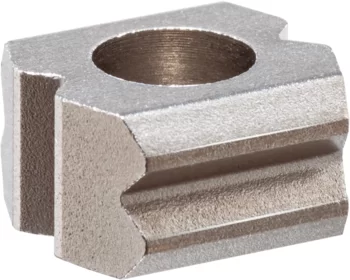

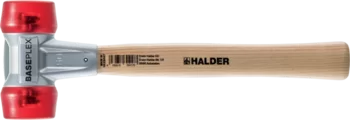

The main benefit of Halder's drop-mallets lies in the fact that they let the user work with greater ease in areas that do not allow for using a hammer on account of the limited available space, e.g. during assembly work on a conveyor belt. Since holding the hammer head directly in the hand, the user applies the impact force with great precision and exactly where it is needed. This minimises the force needed for driving in and pressing in precision parts with the drop-mallet. The steel shot filling on the inside of the drop-mallet provides for work with no rebound and minimum force expenditure, making work easy on the joints. This little helper is fitted on both ends with replaceable, very wear-resistant and splinter-proof heads made of special nylon. Halder makes the drop-mallets available in diameters of 20 mm to 50 mm.

One part for multiple applications

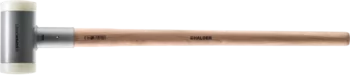

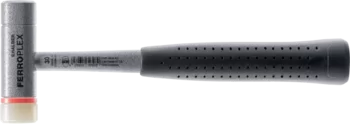

No less convenient and long-lasting during use are the punches Halder makes. Whether they need to drive in rivets, pins, spring pins, bolts, split pins or other fasteners – the punch provides the user with exactly the tool they need to reliably drive such parts in and out. This versatility allows these unassuming tools support the user during assembly, repair and maintenance work – and lets them pair up safely and gently with a steel hammer. The punches are available from stock in diameters of 10, 12, and 15 mm. Both ends are fitted with replaceable, extremely wear-resistant and splinter-free heads made of special nylon.

Volker Gernth: “We have compiled a convenient set of these handy helpers for servicing and maintenance work in the metalworking industry or the automotive and truck sector. A durable plastic box of premium quality offers enough space for two drop-mallets (diameters 20 and 30 mm) and two punches (diameters 10 and 15 mm), making it a cinch for the user to carry them along and always keep the matching tool close at hand.”

Halder offers an easy-to-use, 4-piece PR box set consisting of two drop-mallets and punches each for performing servicing and maintenance work in the metalworking industry / the automotive and truck sector.

Like a soft mallet without a handle: The non-rebound drop-mallets are an ideal choice for places with limited accessibility and perform exceedingly well without any loss of impact force.

The punches made by Halder are perfect for driving rivets, pins, spring pins, bolts, split pins and similar fasteners in and out.

Downloads: